General Tolerance For Sheet Metal Parts

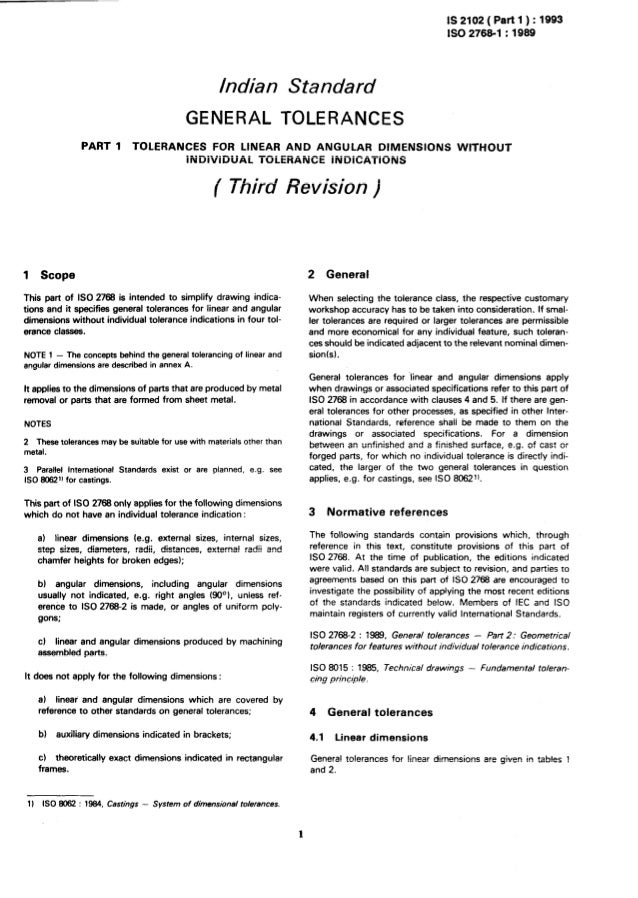

For sheet metal parts iso 2768 mk is used.

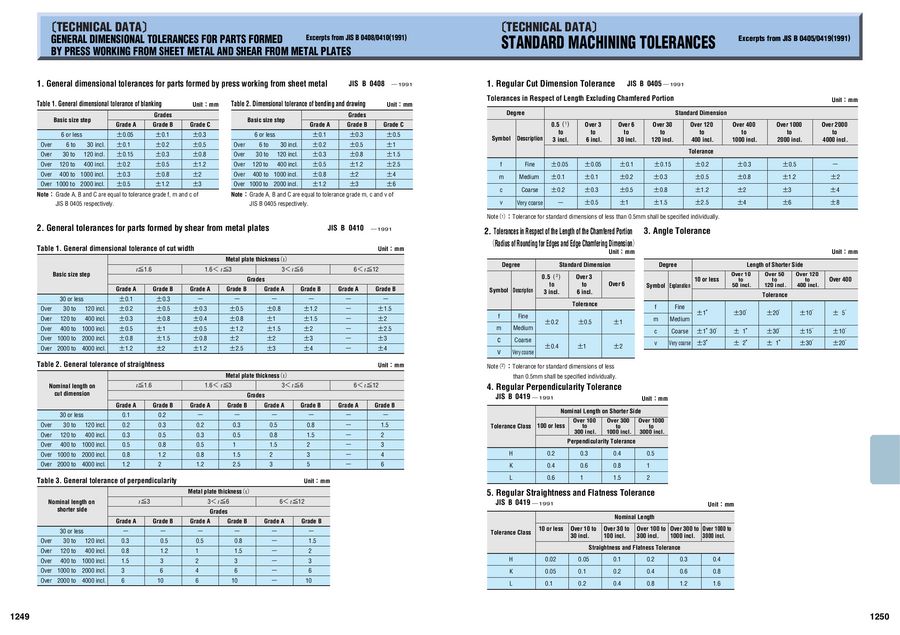

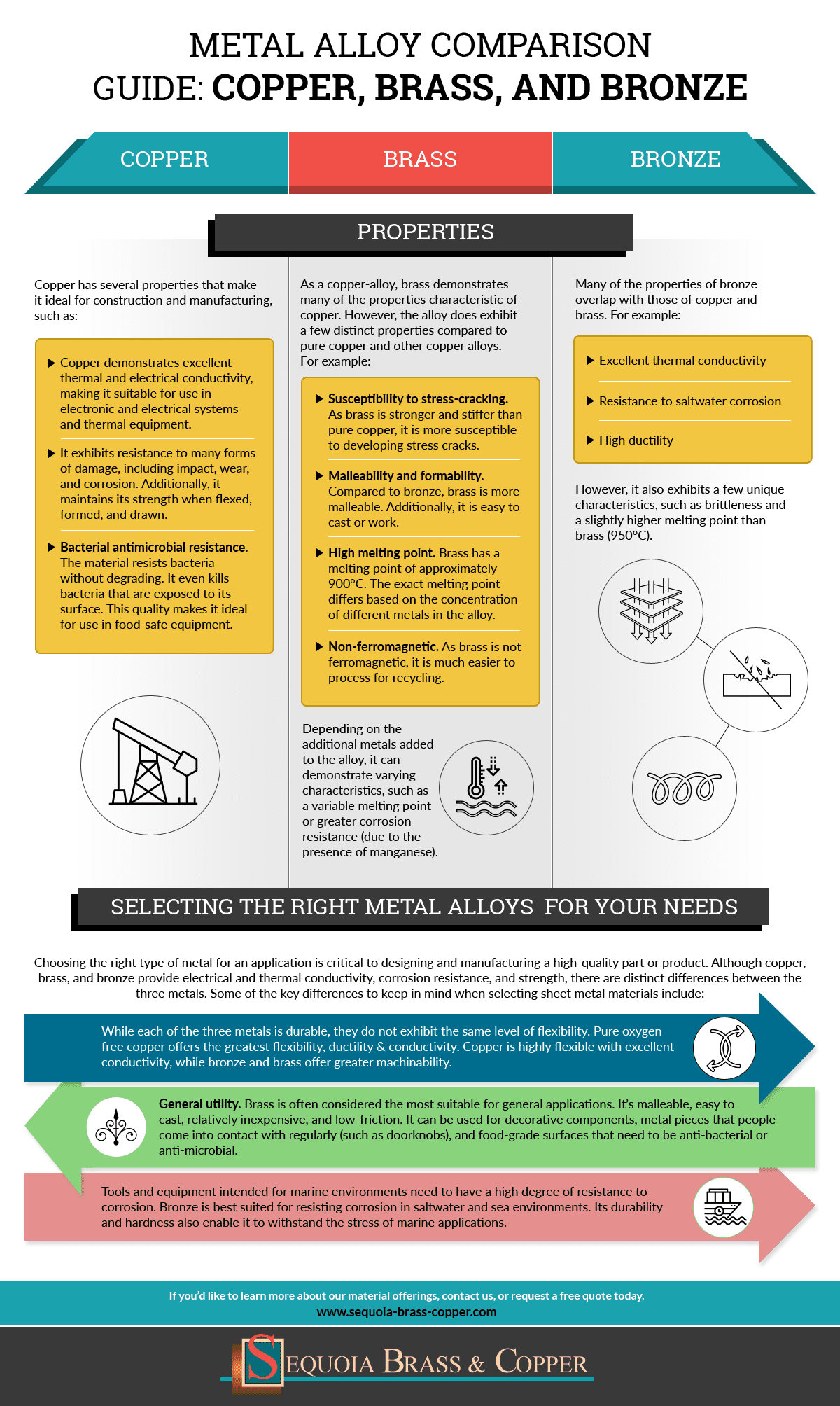

General tolerance for sheet metal parts. 6 or less note grade a b and c are equal to tolerance grade f m and c of jis b 0405 respectively. General tolerance iso 2768 does not specify where to use these tolerances. Fabrication tolerances for dimensional variance in sheet metal and machined parts. Iso 2768 is mainly for parts that are manufactured by way of machining or removal of materials.

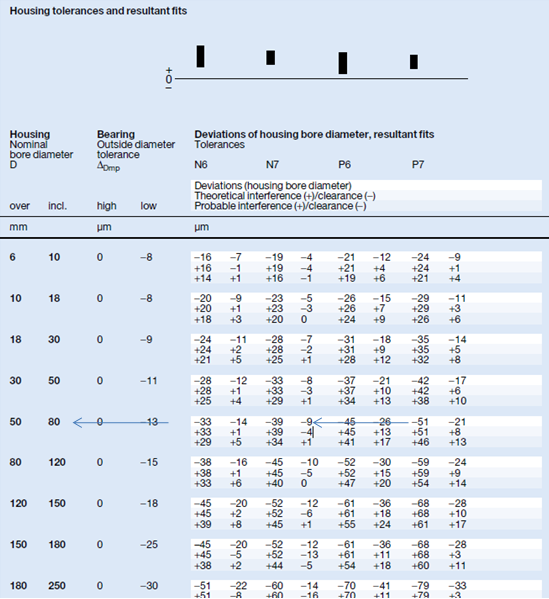

Mm standard dimension grade grade a grade b grade c more than 1000 no more than 2000 more than 400 no more than 1000 more than 120 no more than 400 more than 30 no more than 120 more than 6 no more than 30. Iso 2768 and derivative geometrical tolerance standards are intendedto simplify drawing specifications for mechanical tolerances. General dimensional tolerances for parts formed by press working from sheet metal basic size step grades g rad ea b c over 1000 to 2000 incl. Tolerance class is defined as per design requirements and manufacturing capability.

For sheet metal parts iso 2768 mk is used. General tolerance iso 2768 does not specify where to use these tolerances. It applies to the dimensions of work pieces that are produced by metal removal or are formed from sheet metal. And for machined components iso 2768 fh can be used.

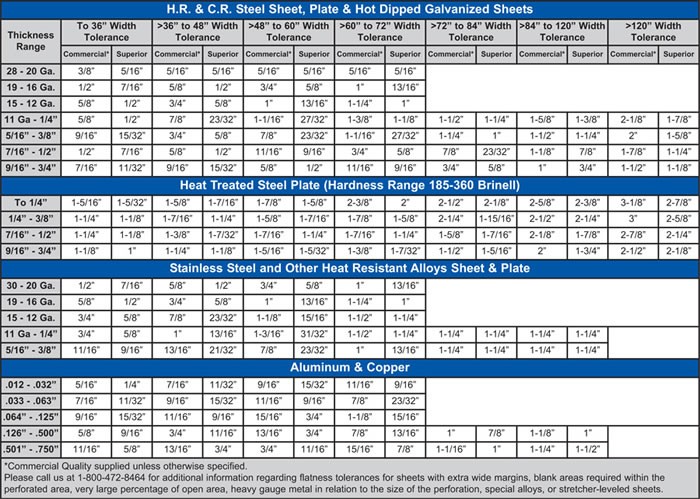

Whichever equipment we use to bend your parts for you there will be tolerances to consider. Over 6 to 30 incl. And for machined components iso 2768 fh can be used. Over 120 to 400 incl.

Variations on dimensions without tolerance values are according to din iso 2768 mk. General dimension tolerance for parts formed by press working from sheet metal jis b 0408 1991 table 1. 1989 general tolerances part 2. Fabrication tolerances for dimensional variance in sheet metal and machined parts overview protocase takes great care to manufacture your electronic enclosures parts and components as accurately as possible.

General tolerances for linear and angular dimensions din iso 2768 t1. All tolerance limits are given in mm. Variations on dimensions without tolerance values are according to iso 2768. General dimensional tolerance of blanking unit mm 1.

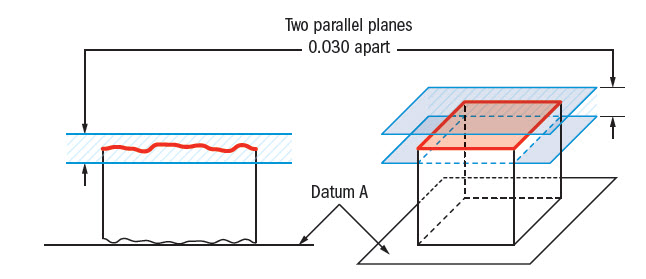

Bends and their corresponding tolerances either pertain to a controlled dimension or an uncontrolled dimension. General tolerances to din iso 2768 the latest din standard sheet version applies to all parts made to din standards. General tolerance on machined parts this this the tolerance table intended to simplify drawing indications and specifies general tolerances in four tolerance classes. Over 30 to 120 incl.

In the above example m and k has defined the tolerance class.