Frp Sheet Pile Wall

Typical section of the rcc sheet pile is shown in figure below.

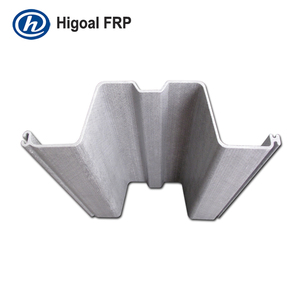

Frp sheet pile wall. Suitable joints can be provided to have a continuous wall. Where environmental considerations require a sheet pile wall structure that will not rot decay rust or spall frp composite is the material of choice. The fiber reinforcement typi cally consists of glass reinforcing fibers. Superwale eliminates the need for timber steel or concrete wale sections.

This type of sheet pile is also referred to as fiberglass or composite sheet pile. Frp sheet piles introduction fiberglass composite piles include round octagonal pipes and sheet piles. Round octagonal pipes general diameters are from 8 to 14 the length can be 4ft 20ft even 30ft. Fiber reinforced polymer sheet piling may also be manufactured of a synthetic fiber reinforced polymer frp.

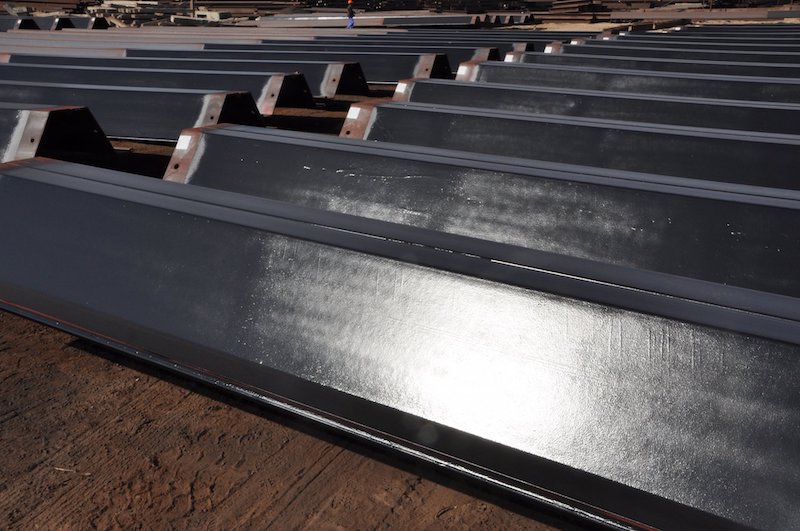

The pultruded frp wale section was specifically designed to replace wood steel and concrete for applications where the environmental considerations require a high strength frp wale section that will not rot rust spall or succumb to marine borers. These piles are relatively heavy and bulky. Frp composite sheet piles are among the strongest and most durable synthetic piling products in the world. The pile length can be increased either by welding or bolting.

Traditional pile materials are steel and aluminum.

.jpg?width=596&name=Annadale%201%20(2).jpg)